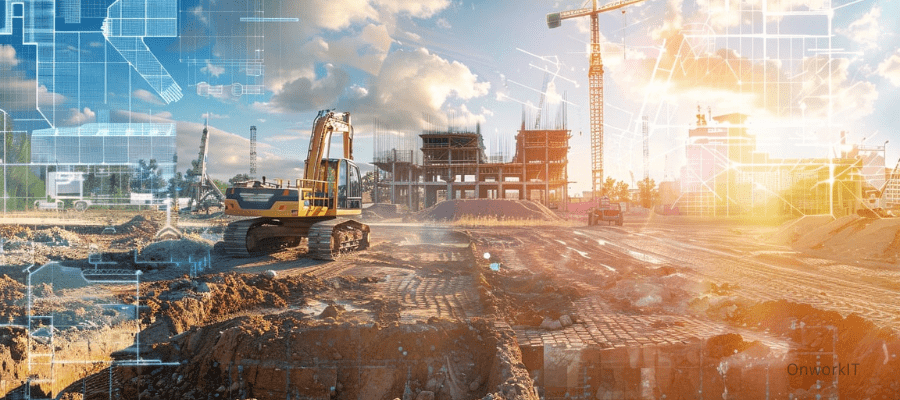

Artificial intelligence is bringing revolutionary impacts across various fields. Compared to industries like healthcare, finance, and home appliances, Application of AI in the construction industry relatively late. AI excels in organizing, analyzing, and identifying patterns in large datasets, offering significant advantages over traditional manual methods. As a result, AI has garnered attention within the engineering sector.

Currently, AI is primarily applied in construction and building in four main categories: (1) planning and design, (2) safety, (3) automation of equipment, and (4) monitoring and maintenance. This article discusses current AI applications in construction engineering and analyzes future developments and challenges.

1. BIM models utilize AI to automate pipeline configurations:

Building Information Modeling (BIM) is a process based on 3D models that facilitates effective planning, design, construction, and management of buildings and infrastructure for Architecture, Engineering, and Construction (AEC) professionals. Autodesk Revit, a BIM software (also known as 4D BIM), allows users to design buildings and internal components in 3D and associate relevant information with time or scheduling to enhance data completeness. This aids in effective communication among owners, architects, and contractors.

3D models must account for architectural, structural, mechanical, electrical, and plumbing engineering. Different contractors use various tools and software designs, often resulting in conflicts during drawing and scheduling, leading to delays and unnecessary rebuilding.

To address this, Building System Planning developed a plugin called GenMEP for the 3D modeling software Autodesk Revit. Using GenMEP, users can automatically design electrical system configurations within building models, considering design specifications and the spatial complexities of different structures.

The automated design utilizes Generative Design, where GenMEP employs machine learning to explore all possible solutions and quickly create 3D models of mechanical and electrical pipelines. This ensures that the paths of these systems do not conflict with the building’s structure, resulting in efficient designs after multiple tests and iterations.

2. Utilizing data analysis and machine learning for engineering risk management:

Autodesk has introduced BIM 360 Project IQ, which utilizes data processing and machine learning to predict potential risks and prioritize them based on severity. The Project IQ software analyzes BIM 360 Field data collected from site audio, imagery, and construction management data. It provides recommendations to site supervisors and quality control personnel to reduce risks.

Volvo Construction Equipment, a Swedish company, launched intelligent compaction systems for soil and asphalt compactors in 2015. They developed AI algorithms within the software called Density Direct, which adapts to new asphalt mixes and pavers, automatically calibrating to meet final density requirements.

3. AI combined with sound and image recognition systems for automatic tagging on construction sites:

Smartvid.io is a platform for managing construction site photos and videos, featuring a ‘SmartTag’ engine. It utilizes machine learning, voice, and image recognition to automatically tag photos and videos from construction sites, facilitating data organization and searchability.

Smartvid.io’s machine learning technology, named VINNIE (Very Intelligent Neural Network for Insight & Evaluation), employs deep learning models to analyze images and voice, automatically tagging construction data and proactively providing safety recommendations to clients.

According to case studies from Smartvid.io and Engineering News Record, VINNIE demonstrated AI’s use in enhancing construction safety by identifying 1,080 construction photos within 10 minutes, correctly flagging 446 photos containing people not wearing safety helmets or reflective vests. This task would typically take 4.5 hours manually. This automated site monitoring adds an extra pair of “eyes” to construction sites, dynamically identifying potential risks and enhancing construction safety.

4. Enhancing comfort through smart building management:

Komatsu from Japan announced a collaboration with NVIDIA to develop AI-enhanced safety systems using the NVIDIA Jetson AI platform tailored for job sites. This system provides real-time interaction and 3D visualization to track personnel, machinery, and objects across construction sites.

Building Robotics, a startup, offers “Comfy,” an application for automated building management. It allows users in commercial spaces and office buildings to adjust central air conditioning based on their comfort preferences. The company claims their platform can instantly respond to user needs by adjusting the central air conditioning in real-time. Building Robotics collaborates with Intel, using Intel’s IoT pathways to connect their Building Management System (BMS) to the cloud. Through the Comfy application, data collected from BMS in commercial spaces enables continuous adjustments and optimization of temperatures across different building zones, aiming to reduce costs and enhance energy efficiency.

5. Enhancing construction efficiency with AI, robots, and drones:

Doxel AI, a startup based in Silicon Valley, focuses on using AI software to improve construction efficiency. Doxel utilizes surveying robots and drones equipped with cameras and LiDAR to monitor and scan construction sites. Visual data is processed using deep learning algorithms, matching it with planned designs and customer requirements to measure construction progress. They compare daily site scans with design models to detect errors promptly.

Japanese construction firm Shimizu recently unveiled a series of construction robots designed to work on building sites. These include a “ceiling construction robot” capable of skillfully installing ceilings, a “welding robot” that automatically completes welding tasks by accurately identifying weld gap shapes, and a “building material transport robot” that autonomously identifies positions and delivers construction materials to work sites.

Meanwhile, mainland Chinese construction companies are introducing a large number of drones to ensure sufficient manpower for projects. They are increasingly adopting information technology, with drones assisting in quality monitoring for tall building projects. This technology significantly reduces the need for manual supervision, especially in checking various quality requirements for high floors, thereby saving time, manpower, and reducing safety risks.

For instance, in the “Fubon New Municipal” project at the intersection of Shizheng Road and Wenxin Road in Taichung City’s Phase VII redevelopment area, a mainland Chinese construction firm is pioneering the use of drones to monitor quality. They use electronic construction plans on tablet computers, enabling all personnel to communicate within the same system. This integration is expected to greatly reduce errors and is planned for application across various projects starting in the second half of 2018. It promises to further enhance construction quality and safety precision in Taiwan’s construction industry in the future.

6. AR Applications in Construction

Suffolk Construction, based in Boston, has opened a Smart Lab in San Francisco to innovate and streamline internal processes. They use VR to tackle cost and labor issues. In the Smart Lab, Suffolk tests new VR technology to monitor progress at job sites. Physical walls give way to VR spaces, allowing clients to wear headsets and freely move around inside buildings. Like Suffolk, other construction firms, developers, and design teams are turning their focus to virtual reality, aiming to address rising costs and reduce construction time with this technology.

Conclusion:

Looking at the lifecycle of a building, it can be divided into three parts: design, construction, and management. In the design phase, AI-generated pipe configurations not only help avoid conflicts with structural designs but also ensure compatibility between pipe design drawings and BIM models, facilitating implementation and verification.

In the construction phase, safety is always the top priority. Image recognition systems can continuously monitor potential hazards. Additionally, using drones and exploration robots instead of workers to enter hazardous areas of construction sites for scanning and visualizing the construction process is a safe and efficient method.

In terms of management, after completion, a building will be used for decades. AI can effectively predict and optimize usage conditions, maintenance and renovation schedules, energy consumption, and more.

A construction project is vast and complex. Introducing AI technology can improve construction in many aspects. While the construction industry has been slower to adopt AI, its comprehensive impact should not be underestimated.