Idea about Solar Cars, in many parts of the world, the number of electric vehicles (EVs) on the roads is rapidly increasing. In these areas, people are starting to enjoy cleaner air, reduced oil stains in parking lots (and on shoes), and quieter dining experiences along main roads due to less exhaust pipe noise. Engine heat pouring into garages and homes during hot weather is significantly reduced, messy clean-ups at gas pumps are unnecessary, and the operating and maintenance costs of vehicles are lower. What’s more interesting is that the acceleration of electric cars is even stronger than naturally aspirated Corvettes, and their low-speed torque is greater than Jeep’s rock-crawling vehicles, making them incredibly fun to drive!

Indeed, the electric vehicle revolution has already begun. This raises the question: “If we already have electric cars, who cares about solar-powered cars?”

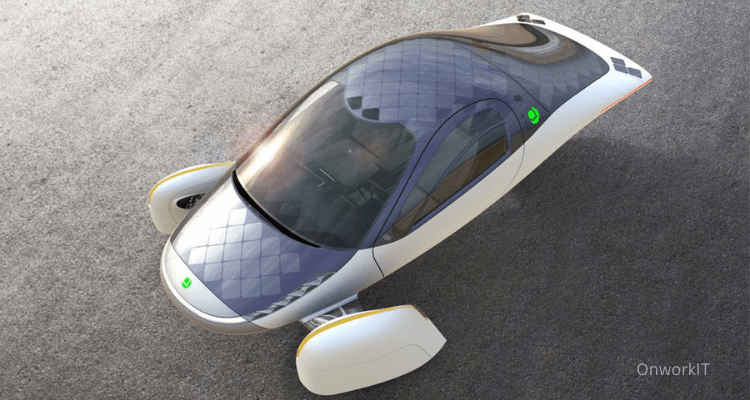

Solar-powered cars lead the way in the electric vehicle revolution. They serve as a testing ground for cutting-edge technology in future electric vehicles. The brilliant minds developing solar-powered cars are the new technology leaders in the electric vehicle revolution and future development.

Renewable energy generation is crucial. Whether it’s solar-powered cars or electric vehicles, they both relate to decarbonization. Electric vehicles can have the greatest and most direct impact on decarbonization. However, electric vehicles face many constraints for achieving market success in large-scale production, while solar-powered cars enjoy more engineering design freedom. Solar car racing teams can explore advanced and even unconventional technologies and design approaches that can address decarbonization issues and its three pillars: electricity generation, electrification of transport, and efficiency, in the real world.

Generating electricity

This involves renewable energy generation, energy storage, and transmission. In the Bridgestone World Solar Challenge (BWSC), “Challenger” class cars complete a 3000-kilometer race entirely on solar power. These cars utilize advanced solar panel Technology and batteries for electricity generation and storage. For instance, BWSC teams have previously used gallium arsenide-based solar cells, which achieve up to 40% efficiency, about twice that of silicon-based cells. Today, solar panels are rarely used in mass-produced vehicles but are increasingly used to supplement electric vehicle charging stations and grid power.

Electrification of transport

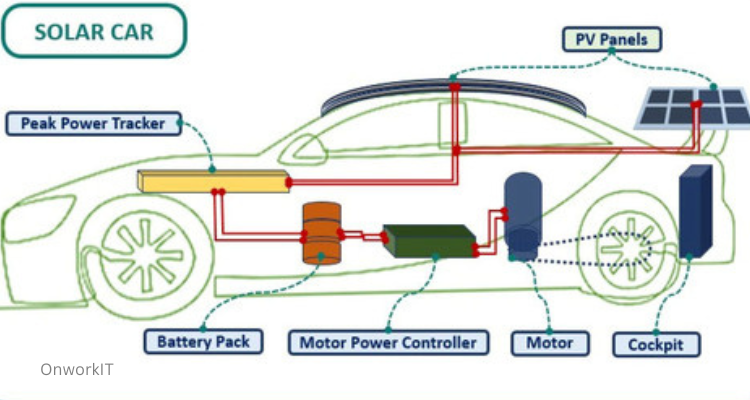

The carbon emissions from fuel vehicles exceed all other emissions combined on Earth, and electrified vehicles can mitigate this. Traditional internal combustion engine (ICE) mechanical systems have been replaced by systems powered solely by electricity. Similar systems are found in solar-powered cars, including batteries, DC-DC converters, and traction inverters.

Critical subsystems in electric vehicles are also electronic: safety, control systems, communication, sensors, and telemetry. In the aCentauri solar car sponsored by PI for the Bridgestone World Solar Challenge, these subsystems are powered by a DC-DC converter based on an improved version of the RDK-747 reference design kit, utilizing Power Integrations’ 750V InnoSwitch?3-EP and PowiGaN? devices.

Efficiency

From solar panels to power application from wheels to road, teams must exhaust all means to improve efficiency—winning the race hinges on power conversion efficiency.

Power conversion stages include converting solar energy to electricity, high voltage to low voltage DC-DC power conversion, such as power conversion in the RDK-747 module based on PowiGaN, gate drivers in power conversion, and power conversion from inverters to traction systems. Teams must also consider physical factors affecting efficiency, such as reducing weight, minimizing rolling resistance, and aerodynamic drag, to achieve optimal performance. Although it has a smaller impact on the entire vehicle, the RDK-747 module can reduce component count, thereby reducing the size of printed circuit boards (PCBs) and eliminating the need for heat sinks, all contributing to reducing the weight of DC-DC power converters.

In terms of decarbonization, it is this leadership and passionate focus on end-to-end energy efficiency improvements that will have the greatest impact on achieving sustainability.